Cases

Cryostar’s Saturation System Transforms Truck-Fuelling Stations

Cryostar's pioneering approach to truck-fueling stations integrates Vahterus' compact and high-efficiency cryogenic heat exchangers. This transformative solution optimizes energy consumption and environmental impact, marking a significant shift in LNG applications.

Benefits of Plate & Shell technology in LNG applications

The use of natural gas around the world is growing and in energy production, the traditional oil and coal are expected to be eclipsed by natural gas use in the coming years.

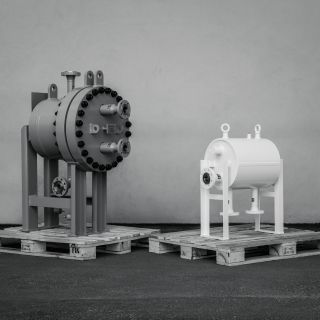

Large Reboiler Units and Heat Exchangers to Ningxia in China

Ningdong, situated 900 kilometers west of Beijing, is poised to emerge as a key hub for petrochemical refining of mineral coal in Asia. With an estimated 27 billion tons of mineral coal deposit, the facility aims to boost industrial capacity, producing 20 million tons of finished products annually within the next decade.

Vahterus Ring - An Energy-optimised Ski Tunnel Using Natural Refrigeration

Read the case about Vahterus Ring, a game-changer in ski tunnel technology located in Uusikaupunki, Finland. Unveiling a pioneering approach to energy optimization, this 1 km tunnel utilizes natural refrigeration powered by carbon dioxide, with independently adjustable units ensuring precise temperature management. Its innovative design not only guarantees a reliable ski season but also showcases a sustainable model by storing and reusing snow during the off-season, setting a new standard for environmentally conscious engineering in winter sports facilities.

Global Challenges Drive Innovation at Pannonia Bio’s Ethanol Plant

Pannonia Bio's ethanol plant not only leads in green innovation but exemplifies collaborative success. Since 2012, the company has grown into Europe's largest ethanol facility, with Vahterus playing a pivotal role in its transformative journey towards one of the most efficient refinieries in the world.

Recovery of Heat from Vapour Produces Savings at a Tyre Factory in China

In Chongqing, China, a tire factory's efficiency greatly improved with Spirax Sarco's Vahterus Vent Condenser, eliminating vapor waste and slashing annual natural gas usage by 300,000 Nm3. Installed in 2015, this maintenance-free solution continues to optimize operations, delivering savings and sustainability in tire production.

Entering Into Low-Carbon Economy Utilising Cold Energy Recovery

Leveraging Vahterus technology, a chemical plant in Eastern China unlocked significant cost savings and reduced steam consumption. By harnessing Vahterus Plate & Shell heat exchangers, they recovered cold energy from ethylene, resulting in a remarkable 7.6 million RMB savings in just six months. This innovative approach not only optimizes efficiency but also propels the company into a low-carbon economy for a sustainable future.

Chinese Edible Oil Refinery Plants Operate with Vahterus Heat Exchangers

Discover how Vahterus, in collaboration with Oiltek Oil & Fats Engineering, has transformed the deodorization process, enhancing energy efficiency and operational reliability for leading edible oil-refinery plants in Tianjin, Shanghai, and Dongguan.

How Fermion Discovered Vahterus: 18 Years, 43 Plate & Shell Heat Exchangers

In a fortuitous encounter at Achema exhibition in Germany, Fermion's Maintenance Manager, Kai Hassinen, stumbled upon Vahterus Plate & Shell heat exchangers in 2001. Now, 18 years later, with 43 installations in their processes, these innovative heat exchangers have not only met – but exceeded Fermion's expectations, standing as a testament to the PSHEs reliability and durability in the challenging conditions of pharmaceutical production.

Solution for Efficient Steam Recovery Found with Vahterus Vent Condenser

At the end of 2009, technicians at DONG’s combined heat and power plant (acquired by VEKS in May 2012), in Köge, Denmark, contacted one of our distributors about the replacement of an existing heat exchanger.