Recovery of Heat from Vapour Produces Savings at a Tyre Factory in China

A South Korean tyre manufacturing company has production facilities in Chongqing, China. The manufacturing process requires an air separator for discharging air. In the air separating process, the water supplied to the air separator is heated up to a saturated temperature using steam, and oxygen, carbon dioxide and other gases dissolved in the water are discharged in accordance with Dalton’s law of partial pressures.

In a typical case, there is a bleed valve and a pipe located above the air separator tank. Through them, gas and steam are discharged into the atmosphere in the form of vapour. This solution is not ideal, however, since it increases steam consumption. An added downside is the white cloud of vapour which is not something that anyone wants to see exiting from a factory.

Vahterus has delivered many heat exchangers for the recovery of heat from exhaust vapour. Spirax Sarco, a company specialising in steam applications, suggested installing a heat recovery system to the customer. In the proposed system, heat energy recovered from exhaust vapour is used to pre-heat cold feed water before it entering the boiler. The key question was the selection of an ideal heat exchanger.

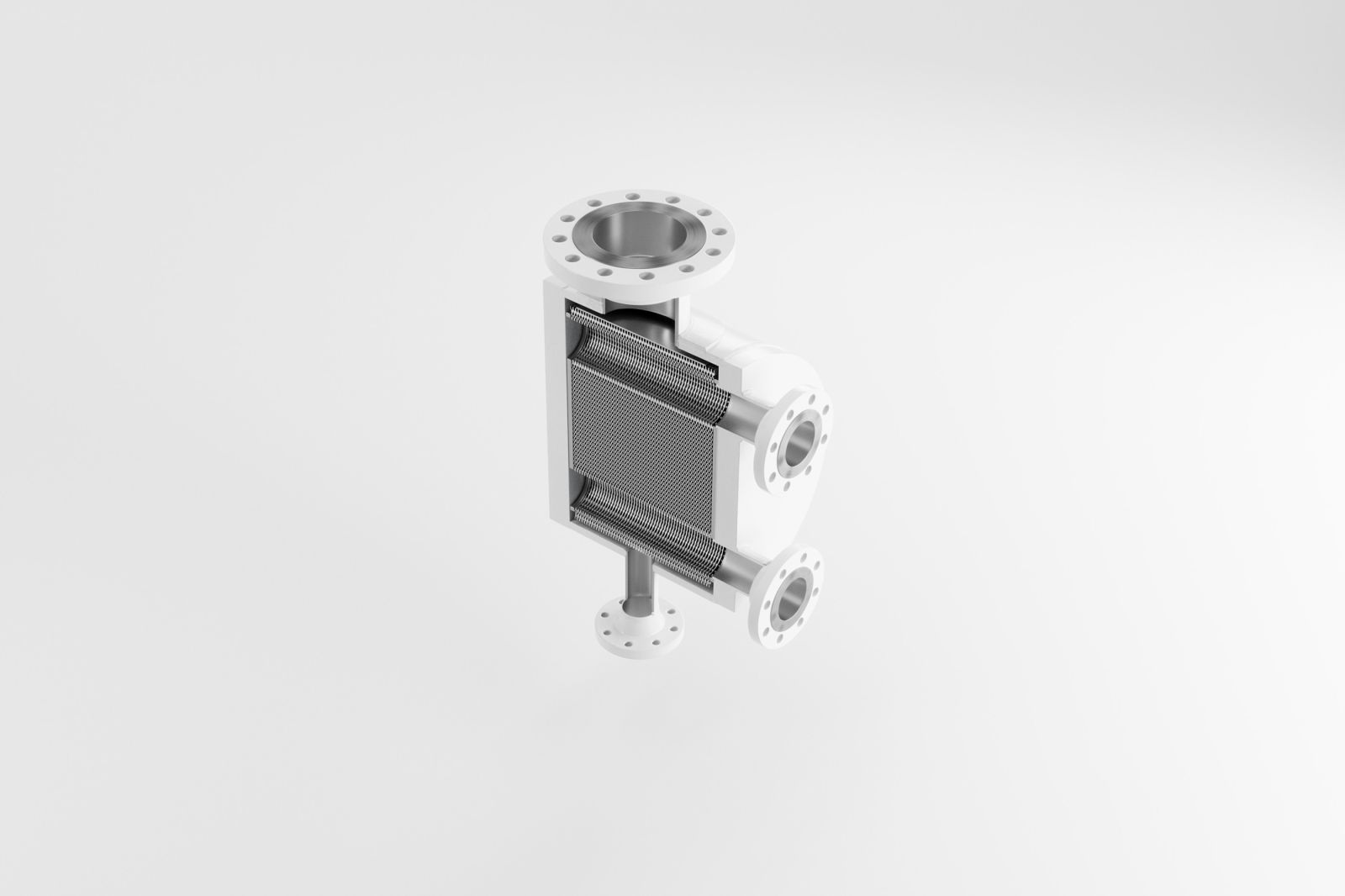

In this case, the heat exchanger was subject to various special requirements. First of all, it should not prevent any non-condensible gases from being discharged into the atmosphere. It should be small and light so that it would be easy to install above the tank. In addition, its structure should be durable and should not need any significant maintenance, since it would be located outdoors. Finally, the heat exchanger should be easy to fit and install in the current system.

Spirax Sarco recommended the Vahterus Vent Condenser to the customer. This unique product is designed to recover vapour and use its thermal energy to heat process water.

Key benefits of the Vahterus product for the customer:

- Steam inlet nozzle customised to volume of steam

- Small plate size and short distances

- Low pressure losses, no back pressure

- Customised condenser unit size

- Separate exhaust nozzle for non-condensible gases

- Easy to install in the existing system

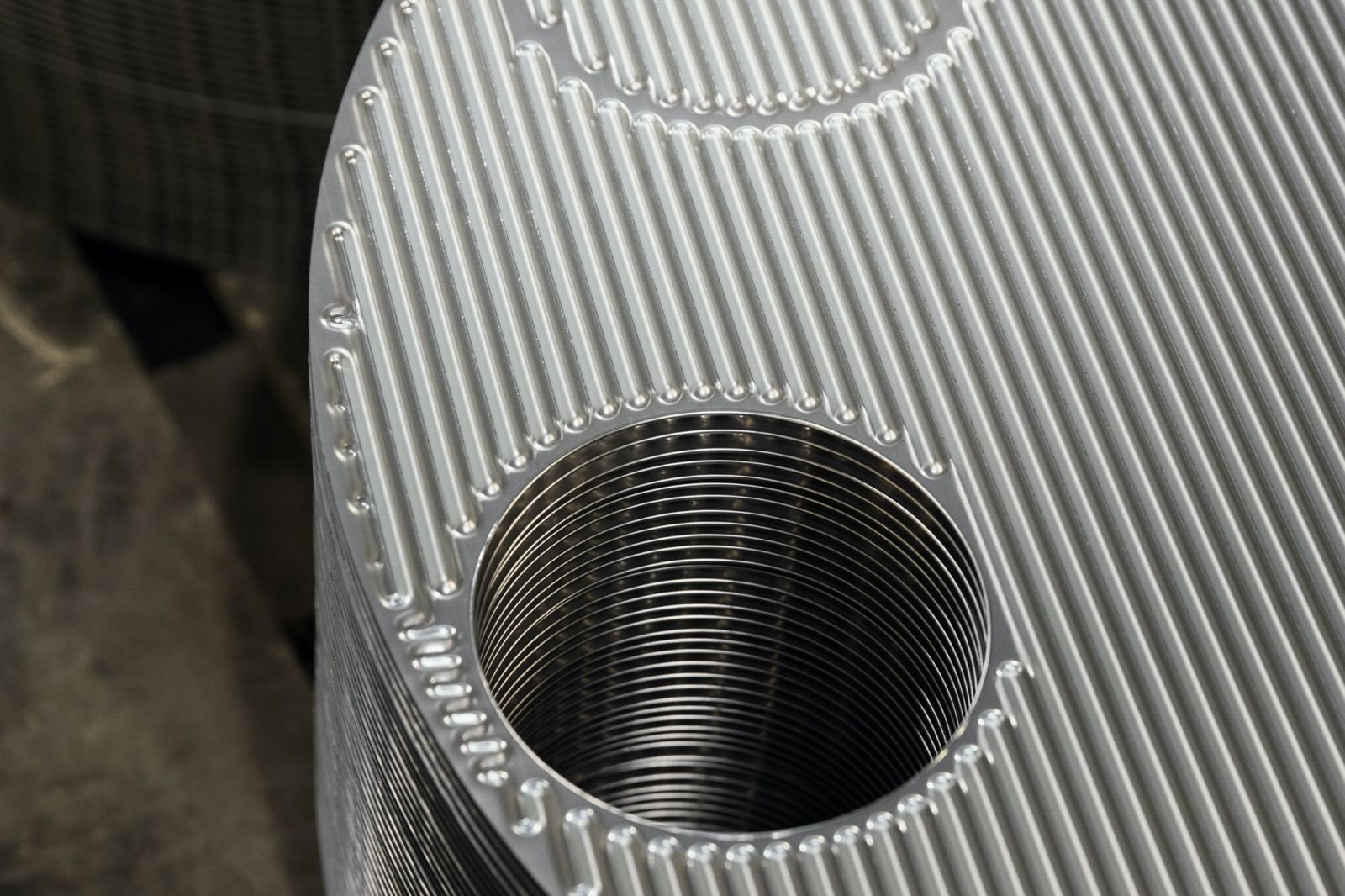

- Durable welded structure, made fully from round plates

- High efficiency ratio, can be fitted in a small space

The tyre company immediately approved the solution proposed by Spirax Sarco, and it was installed in 2015. Since then, no vapour has been exhausted as waste energy. The Vahterus Vent Condenser increases the temperature of 25°C the boiler feedwater supply by. This provides the company with annual savings of 300,000 Nm3 of natural gas used to heat water, resulting in significant financial savings. The new condenser quickly proved its worth as a profitable solution. Four years after its installation, the heat exchanger is up and running and, so far, has not required any maintenance.

Vahterus Vent Condensers have been sold through an OEM partner in China since 2013. Up to now, hundreds of condensers have been installed in China and Japan

Download the case study as a PDF

Transform your project with Vahterus Expertise

Interested in working with us? Our team of experts are ready to collaborate with you. Contact us today to embark on a journey towards cost-effective and energy-efficient heating solutions.

Discover more of our Customer Stories

Chinese Edible Oil Refinery Plants Operate with Vahterus Heat Exchangers

Tracy Hakala, Vice President for Vahterus APAC China is famous for its wide variety of culinary options and flavours. An important element...

CO2 Cold Store Operates with Energy Efficiency and Sustainability in Eastern China

Yonghai Yi, Senior Sales Engineer at Vahterus China ...

Large Reboiler Units and Heat Exchangers to Ningxia in China

A large industrial centre focusing on energy generation and the petrochemical use of mineral coal is currently being built in the region...