Improving Safety and Efficiency at Ice Rinks with Accent Refrigeration

Accent Refrigeration Systems of Victoria, British Columbia (BC), Canada, have been designing and manufacturing ammonia refrigeration systems for 30 years. The two major markets in which Accent specialise are high-efficiency refrigeration systems for the ice-skating industry and energy recovery heat pumps for a myriad of applications. By harvesting the large quantity of low-grade waste heat from community ice rinks to be used as a high-quality energy source on the evaporator side of energy-recovery heat pumps, Accent are able to produce exceptionally high COPs, resulting in very happy customers on both ends of the refrigeration spectrum. One great example of this reliable energy- recovery technology is the Westhills housing development in Langford, BC, where Accent’s ammonia heat pumps have been efficiently heating close to 800 homes for almost ten years.

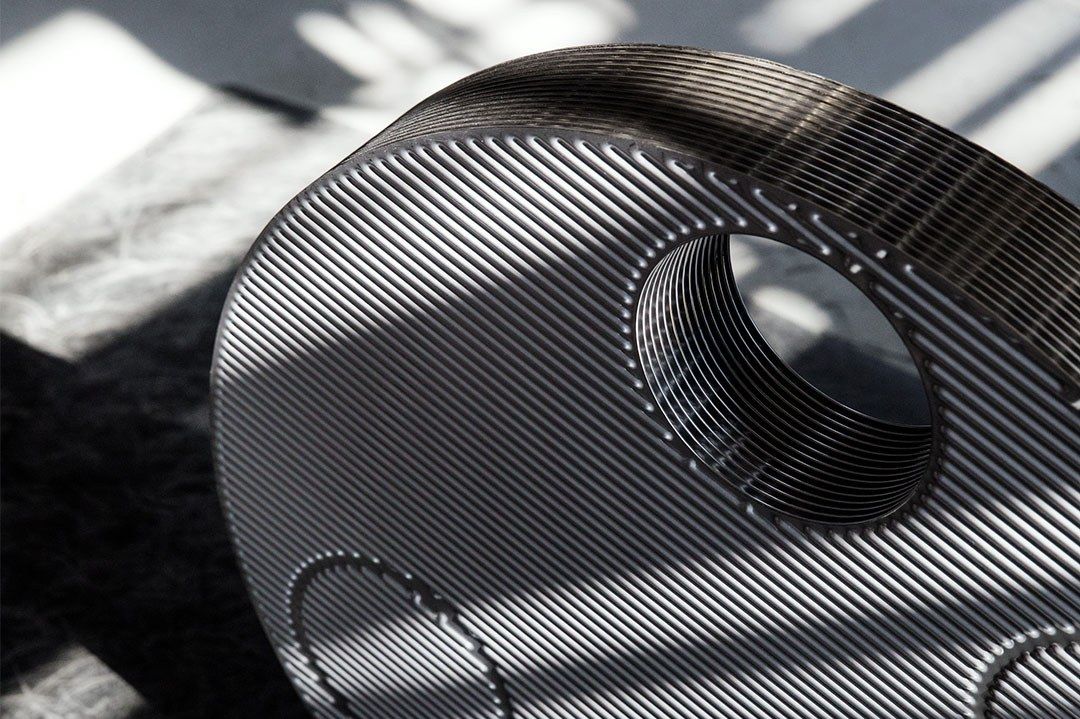

Always on the lookout for ways to lower the refrigerant charge, improve safety, reduce leaks and to improve efficiency, Accent Refrigeration’s founder, Art Sutherland, was introduced to Vahterus heat exchangers at the Chilventa trade show in Nuremburg, Germany, eight years ago. The timing of the introduction was perfect in that Accent Refrigeration was in the early stages of designing an ammonia / CO2 ice rink for a project in South Africa and the Vahterus heat exchangers were perfect for this high-pressure application. The ice rink was completed at The Grove Mall in Johannesburg and was the first of its kind in South Africa. The energy efficiency significantly exceeded the other four rinks owned by the same client, which made it easy to choose ammonia / CO2 for their next rink.

Following the success in South Africa, Accent Refrigeration designed the first ammonia / CO2 ice rink in North America, which was installed at the University of Alaska in Anchorage. The design was also based around Vahterus heat exchangers for both the ammonia / CO2 side as well as the condensing side, where up to 100% of the waste energy was used for preheating the large quantities of fresh air in the main campus building.

Since those early ventures into Plate & Shell design, the Vahterus heat exchanger has become a standard at Accent Refrigeration. It has been deployed for a number of new applications that they are undertaking, including converting high-charge direct R-22 systems to low-charge ammonia, as well as high-temperature two-stage ammonia heat pumps for heating public buildings.

Accent’s three most recent projects have been based on using Vahterus heat exchanges as chillers that use aqua ammonia as a secondary coolant to reduce secondary pumping horsepower while using Vahterus condensers to recover all of the waste heat.

2017 was a tough year for ammonia refrigeration in Canada: three lives were lost in an ice rink when an antiquated Shell & Tube chiller underwent a catastrophic failure while two operators and a mechanic were in the compressor room. These ammonia fatalities where the first in the ice rink industry, which has enjoyed over 125 years with no loss of life.

Following the incident in Canada, Accent Refrigeration led the way in conducting awareness and safety courses across Canada and the USA, reinforcing all positive attributes of ammonia as a primary refrigerant. A major cornerstone in further improving ice rink safety was introducing facility owners to the benefit of low-charge systems that are made possible with Vahterus heat exchangers. Many of the traditional ice rink systems had ammonia charges in excess of 800 pounds, whereas by combining Plate & Shell chillers and condensers, we are getting the ammonia charge down to less than 50 pounds.

When we can improve safety and efficiency, while having no negative impact on the environment by using Vahterus low-charge heat exchangers, it becomes a winning formula for all stakeholders.

Download the case study as a PDF

Transform your project with Vahterus Expertise

Interested in working with us? Our team of experts are ready to collaborate with you. Contact us today to embark on a journey towards cost-effective, sustainable and energy-efficient refrigeration solutions.

Discover more of our Customer Stories

One Vahterus Combined Chiller Cools Two Ice Rinks in Maryland

Jonathan Pascoe, President at Vahterus Americas and Mikko Tuomainen, Key Account Manager at Vahterus In September 2019, Vahterus supplied PSHE 8/6HH460/1/1 unit...

Vahterus Ring - An Energy-optimised Ski Tunnel Using Natural Refrigeration

Vahterus Ring is an excellent example of an energy-optimised sports facility using natural refrigeration....

CO2 Cold Store Operates with Energy Efficiency and Sustainability in Eastern China

Yonghai Yi, Senior Sales Engineer at Vahterus China ...