Vahterus Supplies Heat Exchangers to Urea Plants in Germany

The thyssenkrupp Industrial Solutions has been engineering and building nitrogenous fertiliser plants, based on technology developed by Uhde, for about 90 years, and is a leading supplier in this field. Since 1994 alone, thyssenkrupp Industrial Solutions has provided new ammonia plants, which provide a total production capacity of over 14 million metric tons, as well as upgrading nine existing ammonia plants.

One of the key applications for thyssenkrupp Industrial Solutions is urea plants. Urea is formed by reacting ammonia with carbon dioxide. The urea production process consists of synthesis, recirculation, evaporation, desorption, hydrolysis and granulation. Vahterus Plate & Shell technology is used in the desorption and hydrolysis aspects of the process.

In the hydrolysis part of the procedure, urea and ammonia are removed from process water in order to recycle all the feed components and subsequently re-use the decontaminated water. With the help of the hydrolyser/desorber, all components can then be reused in the plant, which of course optimises the efficiency of the process.

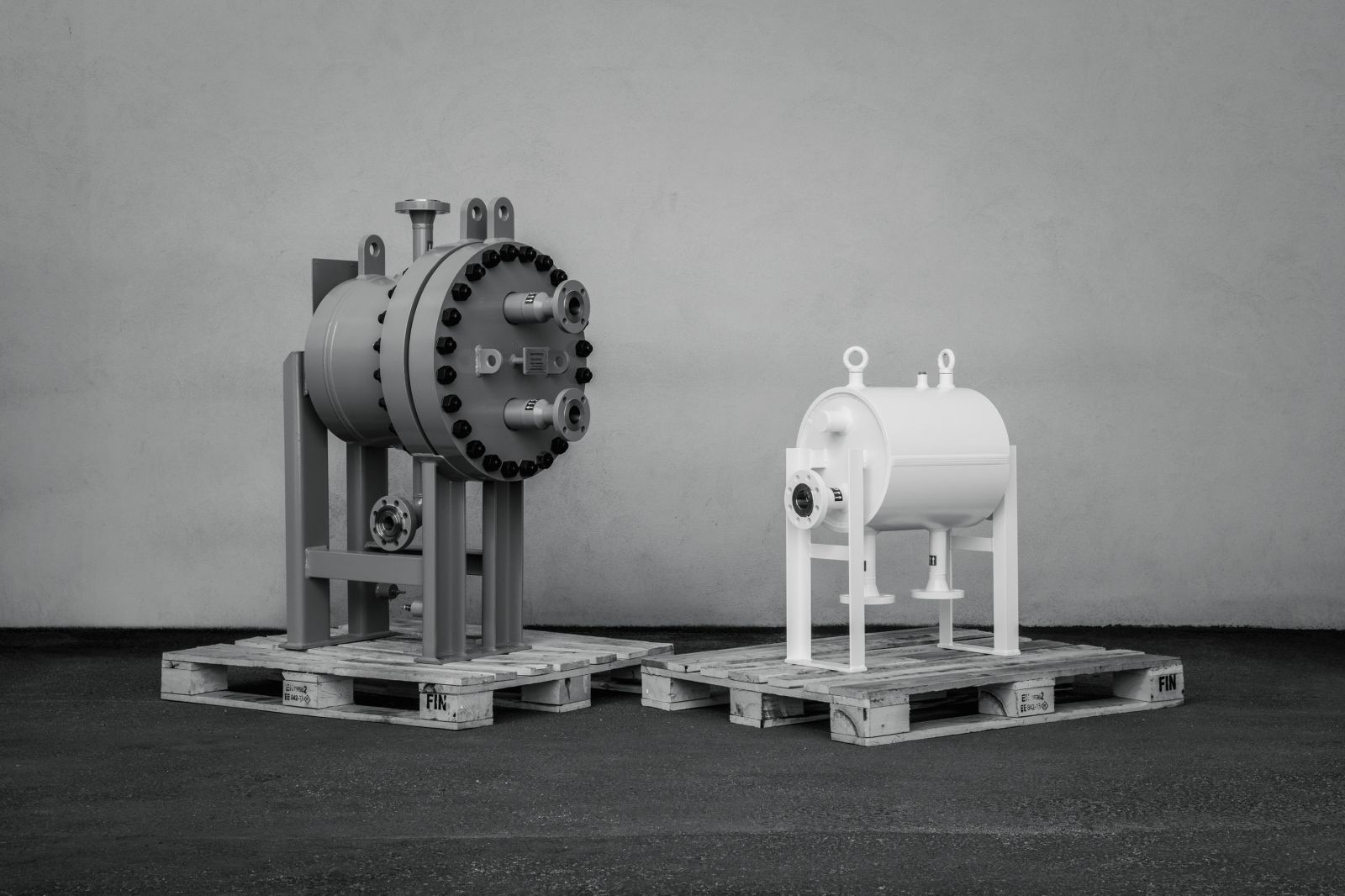

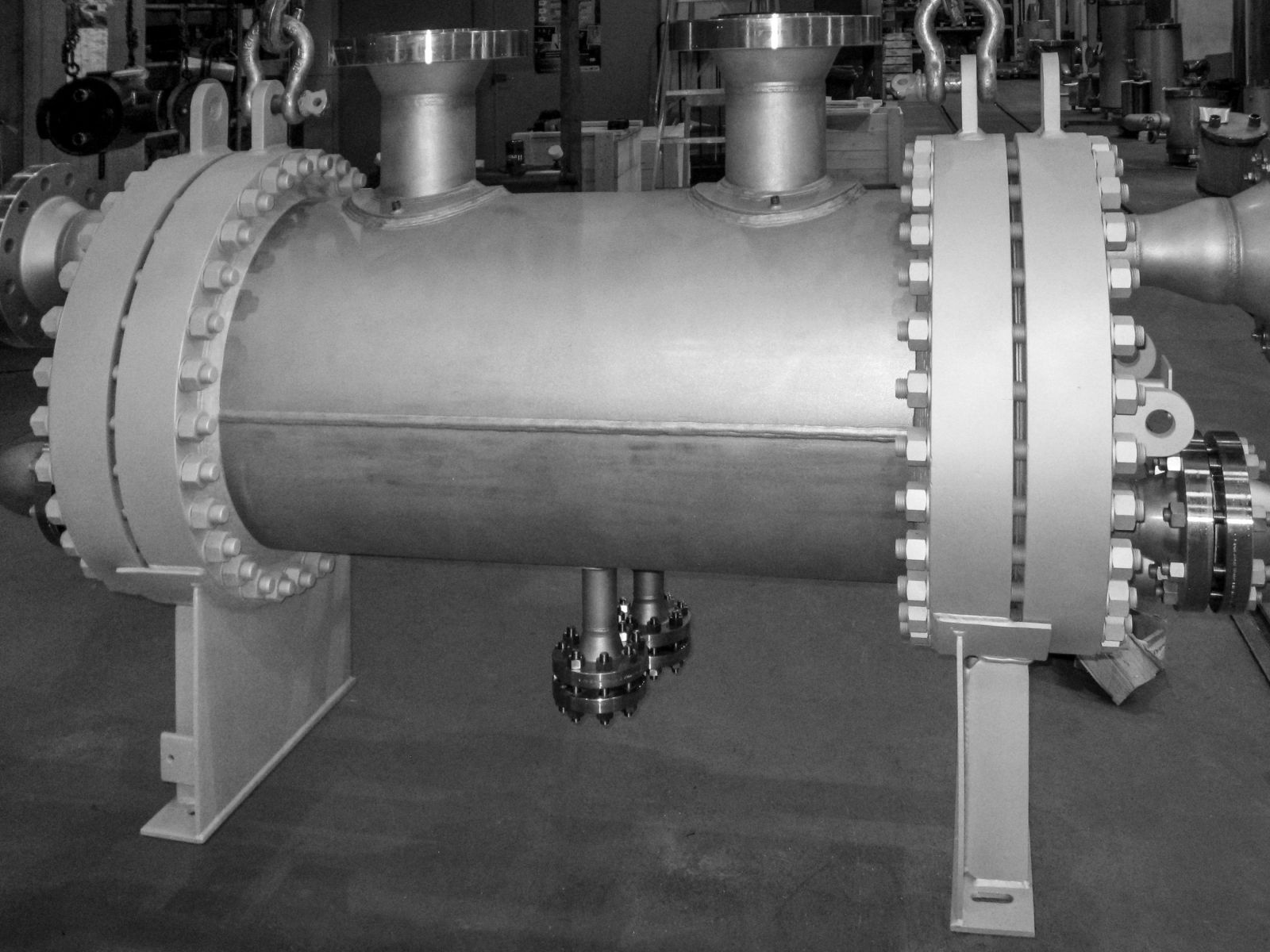

Vahterus heat exchangers are supplied as a standard component in the design of thyssenkrupp Industrial Solutions urea plant. An exchanger is installed between the desorber and hydrolyser. In this ammonia-water cross-heat exchanger, the ammonia water from the hydrolyser is cooled down with ammonia water going to the hydrolyser. The PSHE solution is a double-ended openable model with circulation pipe, which allows for accessibility to the exchanger internals whilst allowing for a multi-pass solution. The multi-pass solution is required, since the temperature profile of the application is very challenging, with a small LMTD and close approach temperature of the streams.

Vahterus has cooperated with thyssenkrupp Industrial Solutions since 2012, and has supplied multiple exchangers for this application. The first unit was supplied to a urea plant located in Turkmenistan, following which there have been installations in the Netherlands, USA, Egypt and Algeria, to name a few of the installations.

When processing ammonia water, there are high demands for safety and inspection in the plant. Therefore, only welded heat-exchanger solutions are considered in this application. Originally Shell & Tube heat exchangers were used, but the systems were very large, often requiring multiple exchangers. Utilising Vahterus’s PSHEs, thyssenkrupp Industrial Solutions has been able to supply a more compact solution at a lower cost.

The thyssenkrupp Industrial Solutions, and its customers, are very satisfied with PSHE in this application, with the exchangers meeting all process requirements as well as providing excellent reliability. The oldest unit has been in service for more than 15 years.

Download the case study as a PDF

Transform your project with Vahterus Expertise

Interested in working with us? Our team of experts are ready to collaborate with you. Contact us today to embark on a journey towards cost-effective, sustainable and energy-efficient heating solutions.

Discover more of our Customer Stories

Vahterus Units Keep Things Running Smoothly at Pölkky Wood Processing Plants

Founded in 1968, Pölkky is the largest privately owned wood-processing company in Northern Finland. The group’s sawmills and further processing plants are...

Global Challenges Drive Innovation at Pannonia Bio’s Ethanol Plant

Pannonia Bio's ethanol plant not only leads in green innovation but exemplifies collaborative success. Since 2012, the company has grown into Europe's...

Chinese Edible Oil Refinery Plants Operate with Vahterus Heat Exchangers

Tracy Hakala, Vice President for Vahterus APAC China is famous for its wide variety of culinary options and flavours. An important element...