NH₃ as fuel for maritime projects

With over three decades of innovation in fully-welded Plate & Shell heat exchanger technology (PSHE), Vahterus brings unrivalled safety and compact performance to ammonia fuel systems. Drawing from proven experience in refrigeration and energy solutions, our heat exchangers now empower the green energy transition at sea and beyond.

Safety built in

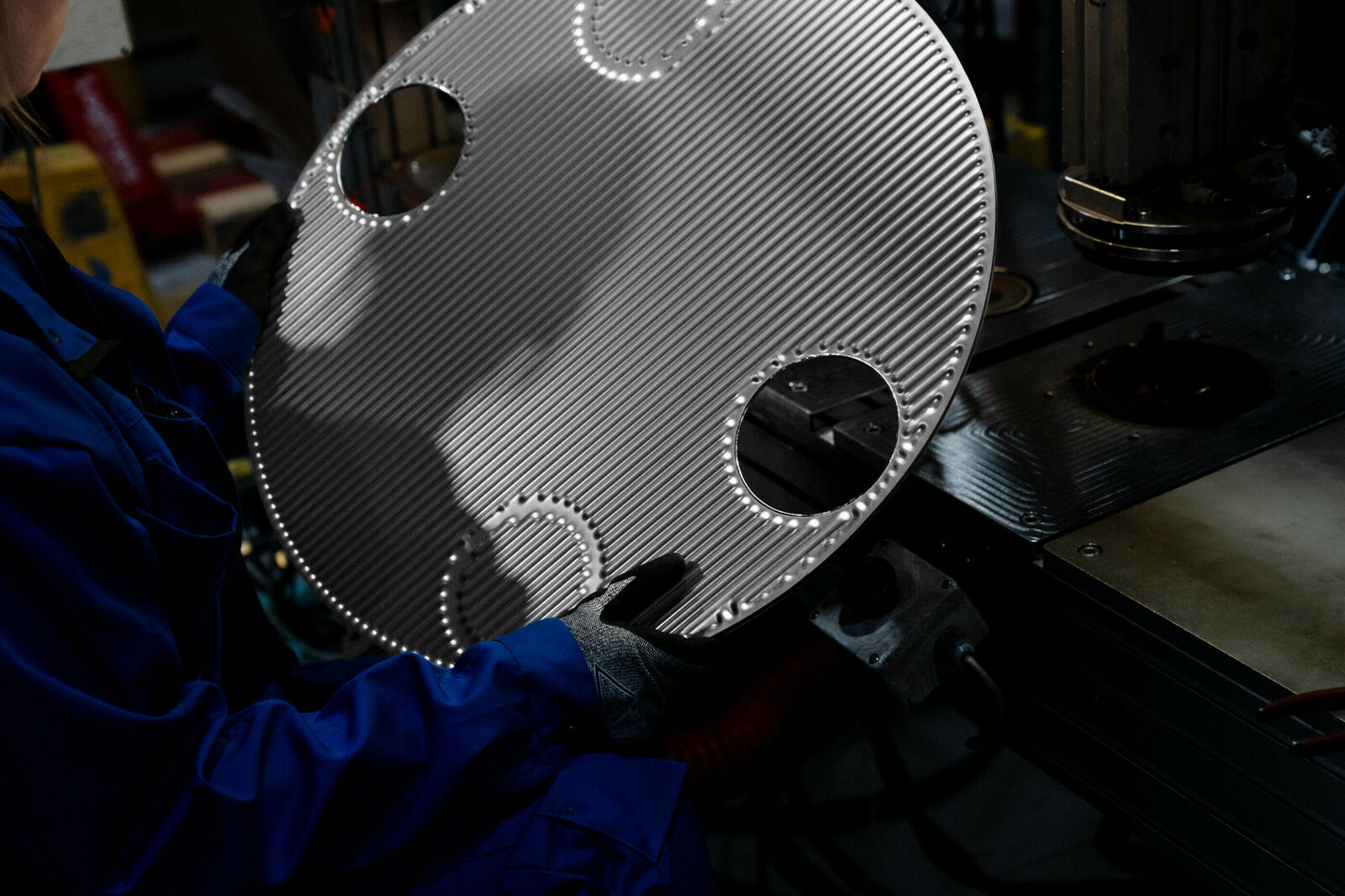

As ammonia is toxic and corrosive, safety is the most important part of ammonia systems. That is why Vahterus Plate and Shell heat exchanger (PSHE) is the most trusted solution. In our solution, we place heat transfer plates inside a protective pressure vessel, using fully welded seams instead of gaskets. This fully welded solution offers users the highest operational availability and safety on the market.

Some heat exchanger professionals talk about permeability regarding gaskets used in both, Plate & Frame, as well as Semi-Welded heat exchangers. Even though it might sound harmless, permeability ultimately means leakage.

Vahterus Plates & Shell units are fully welded, meaning that there are no gaskets on the plate pack. This means no leaks or permeation can happen through gaskets, preventing ammonia odor in fuel handling spaces.

Experience matters

Over the past few years, ammonia as an alternative fuel has moved from talk to action, with companies globally conducting tests and launching maritime projects. This development has been strengthened by classification societies who have been preparing their rules on how ammonia can be safely used in shipping.

It has been a great benefit for Vahterus that we are highly experienced in ammonia heat transfer, with more than 20 years working with ammonia systems. One of Vahterus’ core competencies is ammonia refrigeration systems, where ammonia is condensed, evaporated, heated, and cooled. With experience from thousands of ammonia installations and extensive in-house testing, Vahterus has built a solid knowledge base. Together with our partners, we have developed next-generation solutions for marine fuel systems, for both 2-stroke and 4-stroke engines. Vahterus units have already been successfully tested in different configurations.

Proven in use

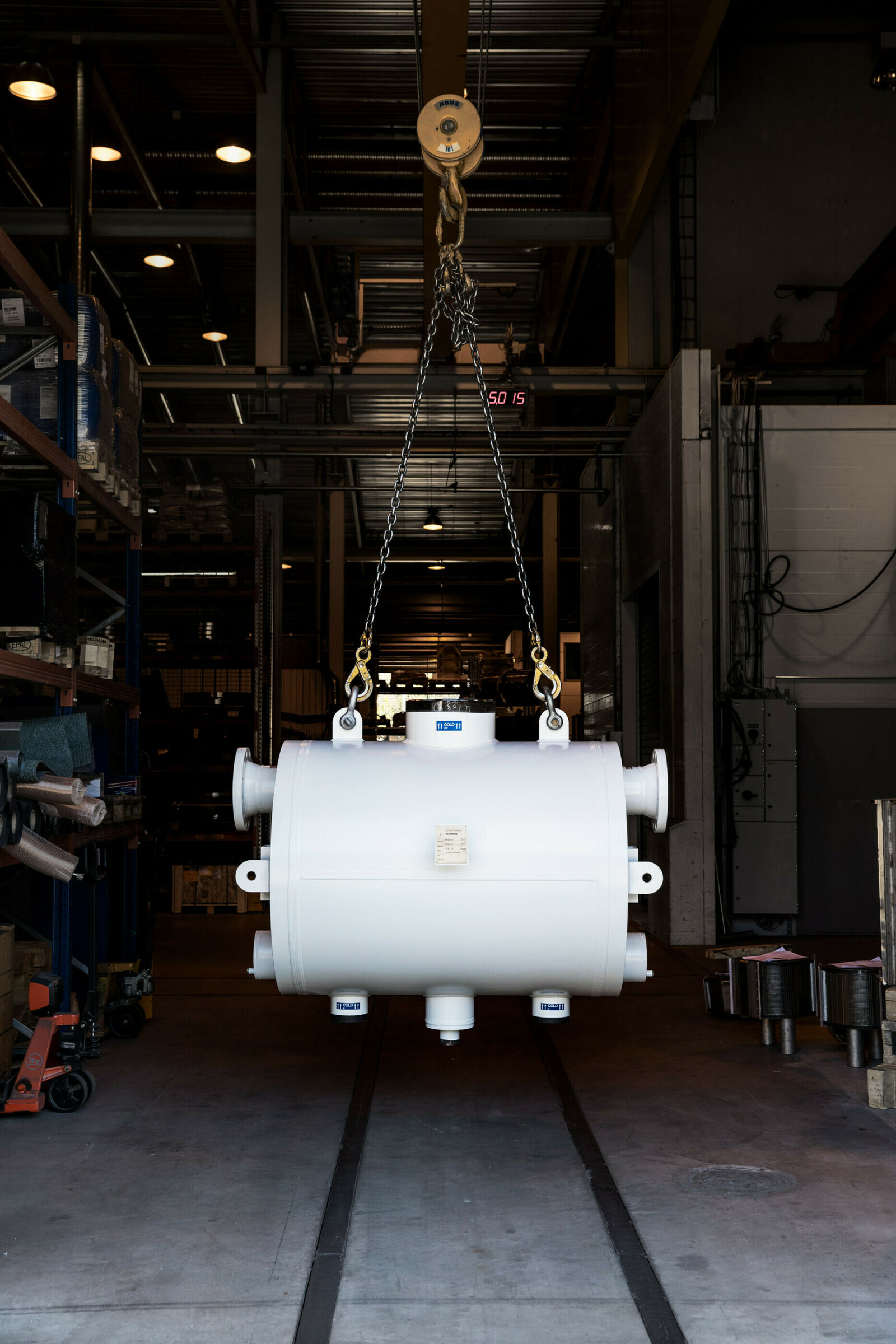

Vahterus Plate & Shell heat exchangers (PSHE) are currently fully viable and available for ammonia marine systems, with first supplies soon in commercial operation. The safety-conscious, cost- and size-effective solution is on the market. But this does not mean we are merely resting on our laurels. To be in the frontline of plate heat exchanger solutions, continuous improvement and development are required.

Vahterus has been designing new, improved solutions specifically for ammonia fuel systems. These designs are currently being verified at Vahterus R&D test center. With the data gathered, optimizations will be made to the PSHE solutions, making them even more suitable for shipowners and operators.

Tailor-made for you

All Vahterus Plate & Shell heat exchangers (PSHE) are designed with customer specifications and requirements in mind. We do not offer ready-made, off-the-shelf solutions, which can often be poorly suited or overengineered for the system in question. As the only company in the world focused exclusively on the design and manufacture of Plate & Shell heat exchangers, we dedicate all our expertise to finding the best solutions for system providers. All PSHE units are optimized to fit the environment and customer needs, to benefit the end user.

Cost

A Fully welded heat exchanger provides very low operational cost for users. No gaskets need to be replaced in the Vahterus Plate & Shell heat exchanger (PSHE). Gasket replacement is a time and money consuming action, that must be done periodically.

Service work requires fuel system isolation and significant safety actions, in addition to the replacement materials and work itself. Such work needs advance planning. Sometimes leakages can happen outside scheduled maintenance, immediately impacting safety and operability. Additionally, no maintenance team can replace gaskets on-site with the same precision as in workshop conditions. This means that the permeability of gasketed units resumes immediately after maintenance.

Shipowners require safety and productivity from their fleet. The fully welded PSHE not only ensures ammonia safety but can also increase productivity in the fuel handling system. PSHE offers a very compact footprint and, more importantly, does not require much height in the fuel handling space, allowing shipowners to use the space more productively.

Environmentally minded

PFAS are often called forever chemicals. These chemicals are harmful for the people, animals and nature. Recycling it is hardly possible and most gasket waste is being typically handled as hazardous waste. Many companies sidestep this topic, focusing their marketing on future use of fossil-free steels as a sustainability point. We have always focused on what can be done today, not just tomorrow.

As a gasket-free solution made from steel, Vahterus heat exchangers are already fully compatible with fossil-free steel and are easily recyclable. At the end of its lifetime, a Plate & Shell unit can be melted back into raw steel. In addition, as a fully tailor-made solution, we are always concentrating on optimizing the unit size and configuration based on the customer’s input. With this approach, we can limit material usage.

Ready to explore solutions?

Our unique Plate & Shell Heat Exchangers are at the forefront of heat exchanger technology for marine applications. If you would like to learn more about our Plate & Shell Heat Exchanger solutions, please get in touch with our experts via the button below.