Vahterus has delivered over 500 customised heat exchangers to LNG applications

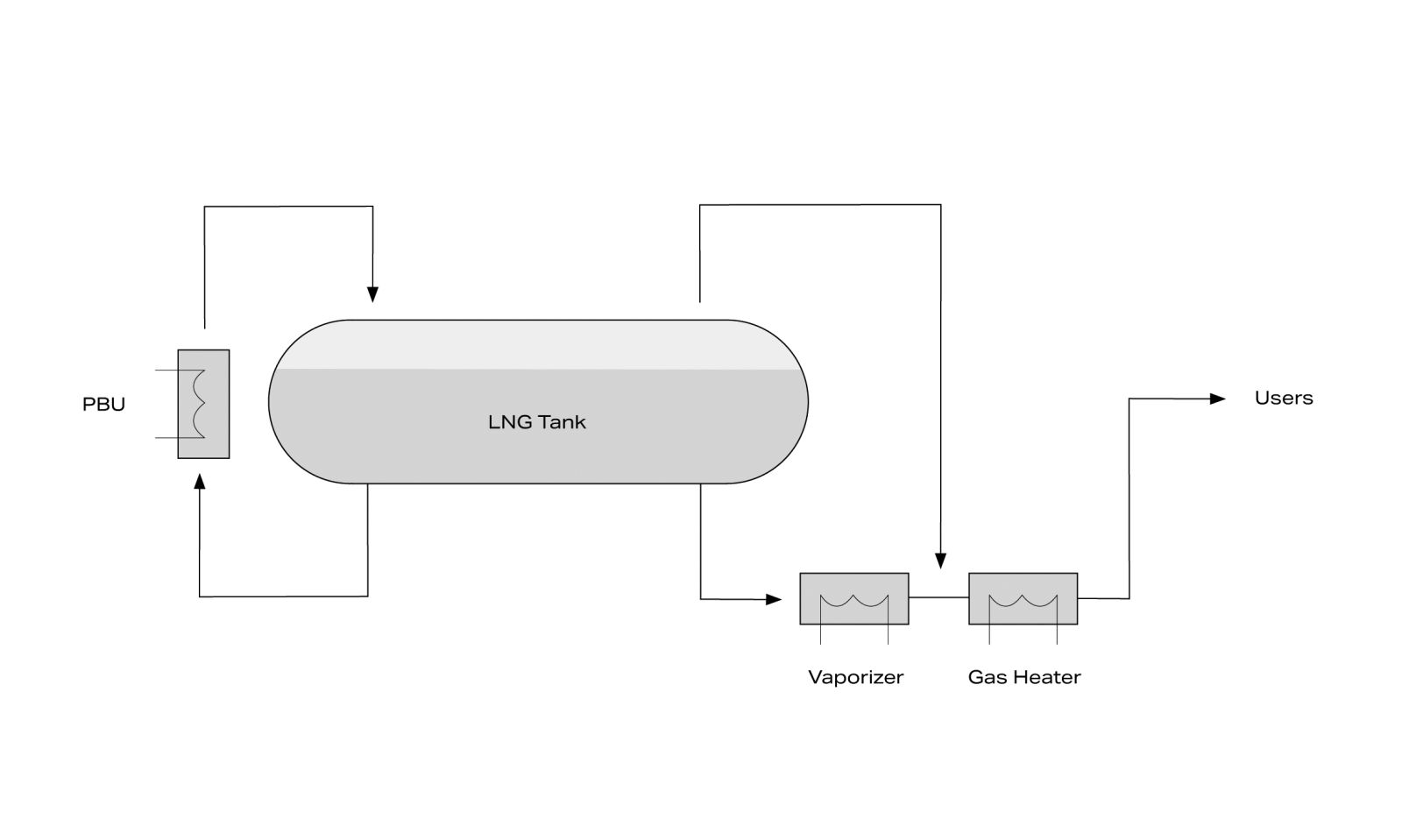

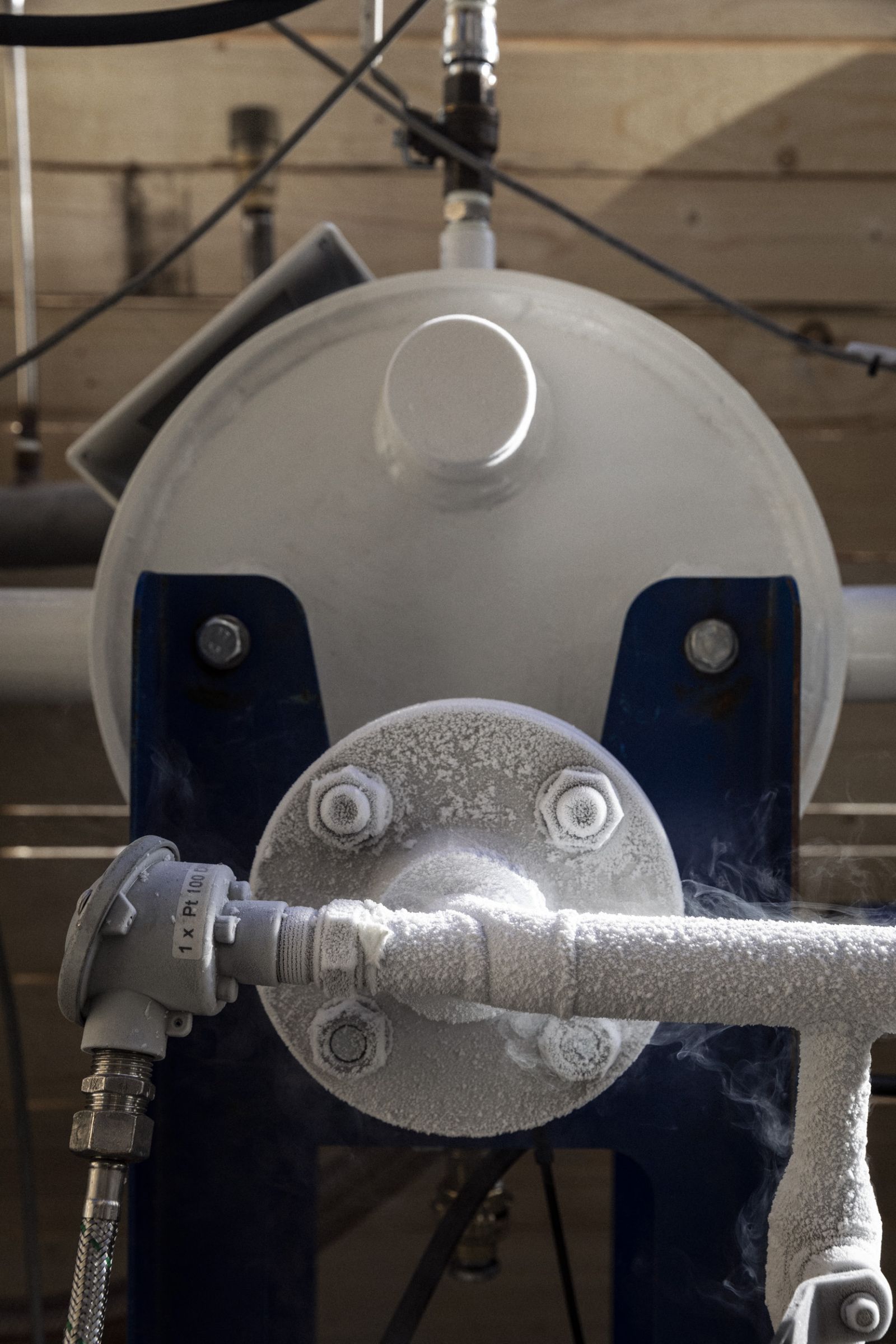

To make natural gas transportation easier and more cost effective it is liquefied, which reduces the volume by approximately 600 times. Liquefaction of natural gas takes place at low temperatures. Depending on the mixture of LNG (methane, ethane, propane, butane etc.) the vaporisation temperature at atmospheric pressure is around -162°C. The low temperatures in combination with cyclic loading makes this a demanding application. The Pressure build-up unit (PBU), for example, has to be able to handle tens of thousands of cycles. Vahterus Plate & Shell Heat Exchanger’s high resistance against thermal cycling has been proved with both practical tests and analysis. Along with its efficient use of stainless-steel materials, this makes it very competitive in this application. It is widely used in the LNG industries, with more than 500 units delivered.

The main gas evaporator (MGE) can be designed to handle super heating, making the system even more compact. The superheating for the boil-off gas (BOG) can be handled in a separate unit or integrated into the MGE. Combined with the space saved and the efficient use of materials compared to Shell & Tube heat exchangers, this makes PSHE an extremely attractive alternative.

LNG Fuel System with PBU

Transform your LNG-project with Vahterus Expertise

Interested in working with us? Our team of experts are ready to collaborate with you. Contact us today to embark on a journey towards cost-effective, sustainable and energy-efficient heating solutions.