PSHE Construction

The principle of a heat exchanger is to transfer heat from the primary to the secondary side through a heat-transfer plate that separates the flows. Vahterus heat exchangers are used for heating, cooling, condensing, evaporating and the recovery of process heat. They are composed of a fully welded pack of circular heat-transfer plates installed in a cylindrical steel shell – hence the term Plate & Shell. The nature of the construction provides a short and efficient flow path for the product whilst maintaining low pressure drop. This heat exchanger type is thus ideal for applications with viscous fluids. There are no gaskets used in the construction and all connections are welded.

Due to this unique construction, Vahterus Plate & Shell Heat Exchangers can meet very demanding design conditions:

Mechanical design

- Full vacuum to 150 bar

- From -196°C to +600°C

All Vahterus heat exchangers are designed with the required design codes, such as:

Design code

- AD-2000

- ASME VIII, Div.1

- EN 13445

- Lloyd ́s Register

- R.I.N.A.

- ABS Europe Ltd

- Bureau Veritas

- PD5500

- DNV GL Marine

- KGS South Korea

- EAC

- Others on request

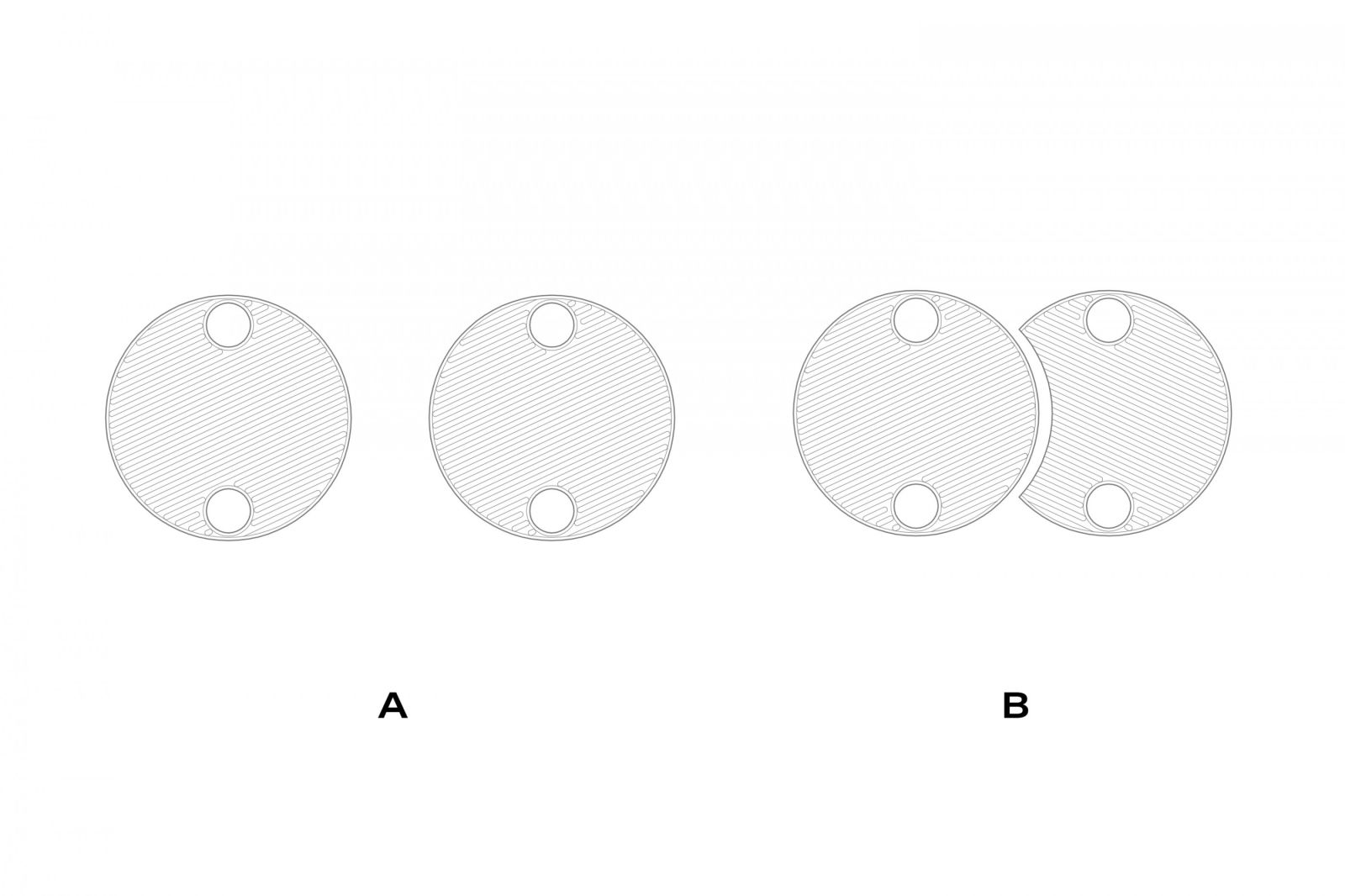

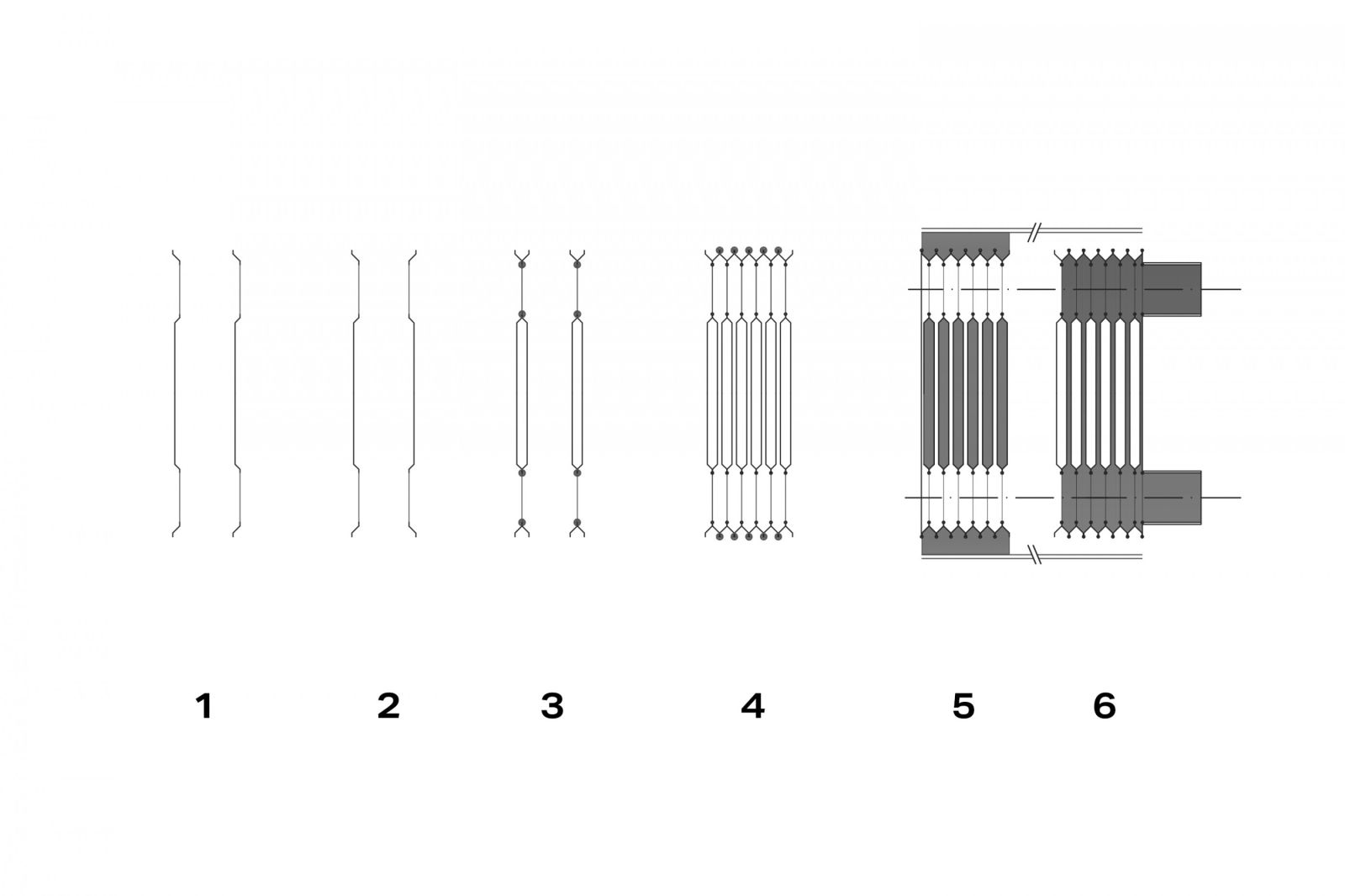

Plate Pack

The most common form of the heat exchanger is assembled from a stainless-steel plate pack and a shell made of carbon steel or stainless steel. However, the heat exchanger can also be made in other materials.

The figures below show the basic assembly of the plate pack.

See a video of how the plates are welded together:

Vahterus offers a wide range of plates:

| PSHE model name | Heat transfer area, m2 | Nozzles plate, DN | Nozzles Shell, DN |

|---|---|---|---|

| PSHE 2 | 0.5-5 | 25 | 20-80 |

| PSHE 3 | 1-50 | 50 | 25-250 |

| PSHE 4 | 3-100 | 80 | 25-300 |

| PSHE 5 | 5-200 | 100 | 25-350 |

| PSHE 6 | 6-350 | 125 | 25-500 |

| PSHE 7 | 8-550 | 150 | 25-500 |

| PSHE 9 | 15-1000 | 200 | 25-700 |

| PSHE 12 | 25-1500 | 250 | 25-800 |

| PSHE 14 | 20-2000 | 300 | 25-800 |

The materials used in the plate pack can be selected according to the customer’s needs. We have experience with various materials, with new ones always under test work. If the material you need is not on the list below, please contact Vahterus.

Plate materials

- AISI 316L

- AISI304L

- AISI 904L

- 254 SMO

- Alloy C22, C276

- Duplex

- Titanium gr.1, gr.11

- Nickel

- Others on request

Shell

The shell (pressure vessel) is the protective cover around the plate pack. It is also used to guide the ‘shell side’ flow through the plate pack, and can be tailored to achieve the specific operating conditions.

Vahterus shell design follows the guidelines given by the specific design code. Typically, that is either PED (PED 2014/68/EU) or ASME VIII Div. 1.

Shell sizes, materials and connections can be customised according to the requirements of the process. For more about customisation, click here.

Typical shell materials are listed below:

Shell materials

- Carbon steel

- AISI 316L

- AISI 904L

- 254 SMO

- Alloy C22, C276

- Duplex

- Titanium

- Others on request

Reach out to one of our experts to learn more.