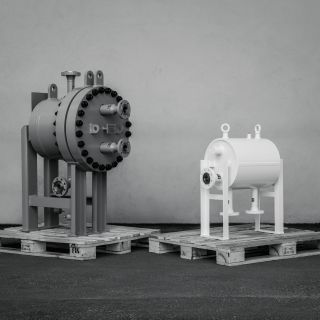

Fast delivery of Hastelloy Heat Exchangers to Kisuma Plant in the Netherlands

Read how dedication and excellent cooperation between Vahterus, Kapp Netherlands and Kisuma resulted in a 31 day delivery of customised heat exchanger solutions.

Read how dedication and excellent cooperation between Vahterus, Kapp Netherlands and Kisuma resulted in a 31 day delivery of customised heat exchanger solutions.

Colonial Pipeline, the largest US refined products pipeline system, spans 5,500 miles from the Gulf Coast of Texas to the Port of New York and New Jersey. Delivering over 100 million gallons of gasoline, diesel, and jet fuel daily, this vital infrastructure facilitates the seamless movement of energy products through 13 states. In 2016, facing maintenance challenges with aging equipment, Colonial Pipeline turned to Vahterus Plate & Shell Heat Exchangers to enhance efficiency.

Omnia Limited's chemical complex in Sasolburg, South Africa, relies on imported ammonia for nitric acid and ammonium nitrate production. In Richards Bay, the choice of Vahterus Plate & Shell Heat Exchangers (PSHEs) by ThyssenKrupp Industrial Solutions South Africa and Zonke Engineering has significantly optimized cost and performance in ammonia recovery systems.

Vahterus Plate & Shell Heat exchangers play a pivotal role in thyssenkrupp Industrial Solutions' urea plants, optimizing the hydrolysis and desorption phases. Since 2012, Vahterus has been a key supplier, delivering compact, cost-effective solutions that meet stringent safety standards. These heat exchangers, used between the desorber and hydrolyser, have proven their longevity and reliability, with the oldest unit surpassing 15 years of continuous service.

In the pursuit of efficient and compact solutions for Gas-to-Liquid, Power-to-Liquid, and Power-to-Gas processes, INERATEC has found a reliable ally in Vahterus Heat Exchangers. Successfully integrated into INERATEC’s container-sized chemical plants, Vahterus PSHEs play a pivotal role in ensuring high thermal efficiency through effective heat recovery and compact heating and cooling, particularly exemplified in the Power-to-Liquid process at their Karlsruhe site, marking a successful collaboration between the two innovators.

Impala Platinum, the second-largest platinum producer globally, faced a critical cooling challenge in their South African mineshafts, where outdated technology and maintenance issues posed risks. This article discusses how they successfully upgraded their cooling system by adopting innovative Plate & Shell heat exchangers, marking a significant shift in technology for large-scale cooling applications.

Pölkky replaced an old tube heat exchanger in Taivalkoski production unit with a fully welded 12-MW Vahterus Plate & Shell heat exchanger. The compact size makes it easier to install in a production plant.

Read about how Panasonic supplied an energy- efficient refrigeration system with Vahterus PSHE to Huachen Group’s green cold store in Eastern China.

Discover how a heat pump project with Vahterus PSHEs in Malmö provides heating to 10,000 homes, saving 50,000 tons of CO2 emission yearly.

In the quest for enhanced safety and efficiency within ice rinks, Accent Refrigeration Systems has emerged as a pioneer. Leveraging Vahterus heat exchangers, this Canadian company has not only revolutionized refrigeration systems in the ice-skating industry but also played a crucial role in fostering safety awareness.