1. Self Cleaning

A correctly designed Plate & Shell heat exchanger has a highly turbulent flow.

This turbulence creates a high wall shear stress, which helps to keep the exchanger free from fouling.

2. Shell Materials

- Carbon steel

- AISI 316L

- AISI 904L

- 254 SMO

- Alloy C22, C276

- Duplex

- Titanium

- Others on request

3. Compact Size

Vahterus PSHE requires only 25% of the surface compared to Shell & Tube heat exchangers, however, it is possible to construct PSHE exchangers with over 2000 m² of heat transfer area.

The compact size of the Vahterus PSHE minimizes installation, operating and maintenance costs, which again saves energy and the environment.

4. Fully Welded

The core of the Vahterus plate and shell heat exchanger is a fully welded plate pack enclosed in a strong shell structure, which eliminates the need for a gasket.

5. Flow configurations

In condensing applications, the steam is on the shell side, with the cold side on the plate side. Shell side (steam) flow enters the exchanger at the top of the shell and the condensate exits at the bottom. Plate side flow is counter-current: the exchanger operates on the counter-current principle.

Steam on the end plate side/cold side in the shell and vent condenser designs are also possible.

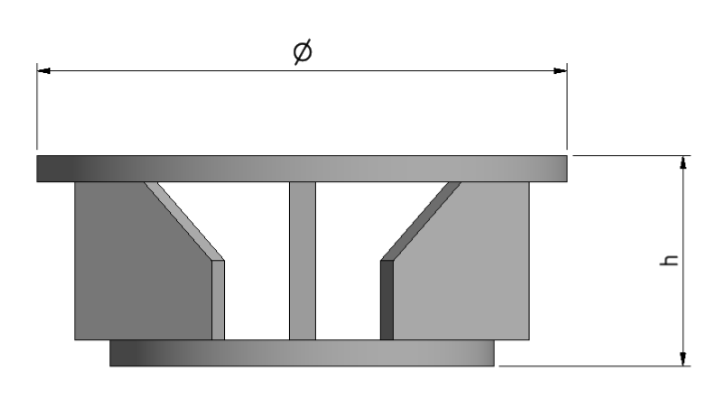

6. Impingement plate,

Water vapor condensers use an impingment plate in the water vapor inlet connection. The small water droplets that accompany the water vapor may damage the plate pack when it hits at a high speed. The purpose of the impact plate is to prevent water droplets from coming into direct contact with the plate stack.

7. Plate Pack Materials

- AISI 316L

- AISI 904L

- 254 SMO

- Alloy C22, C276

- Duplex

- Titanium gr.1,gr.11

- Nickel

- Others on request

8. Plate Pack Construction

The basic heat exchanger is assembled from a plate pack made of stainless steel plates and a shell made of carbon steel or stainless steel.

Video below:

Plate pack construction

Filling boxes