Beauty of Being Compact: Efficient building-heat packages open doors in Canada

Leonardo Berardinelli, Vice-President Production Division at Preston Phipps Inc, Montreal

Since 2010, Vahterus has been providing Plate & Shell Heat Exchangers for building-heat packages manufactured by Preston Phipps for the Canadian Market.

In the early 2000s, there was a change in the approach to providing building heat for the institutional and commercial markets. In the past, contractors put together packages on site, based on drawings and specifications provided by the design consultants. Once these systems were installed, the end-user and maintenance personnel were faced with many different systems throughout their facilities. After the warranty period ended, service became difficult because no single-source vendor was responsible for the system, and facility maintenance staff became increasingly frustrated by having to deal with multiple vendors for support.

As the years passed, buildings aged and so too did the building heating systems. Replacing huge Shell & Tube heat exchangers without demolishing existing architecture was challenging. New buildings were designed with smaller mechanical rooms. The old design model needed to be rethought and a different approach was required.

Design consultants were now looking for packaged solutions that were manufactured and designed by a single-source vendor, who would later be the sole responsible vendor for maintenance and any possible issues. Faced with this challenge, Preston Phipps decided to look at building heat differently. The idea of conventional steam-side controlled Shell & Tube heat exchangers needed updating. Although this design worked well, smaller mechanical rooms and more energy-efficient design criteria meant that it was time to look for alternative solutions.

Since steam was the energy source, the idea of looking at condensate-controlled, or flooded, heat exchanger solutions was the path forward. The design’s simplicity meant better control, less equipment and a smaller footprint. In addition, the market was asking for maximum energy savings, which could be achieved by the sub-cooling condensate. The last challenge was getting away from the traditional Shell & Tube heat exchanger and finding a different technology that was efficient and compact.

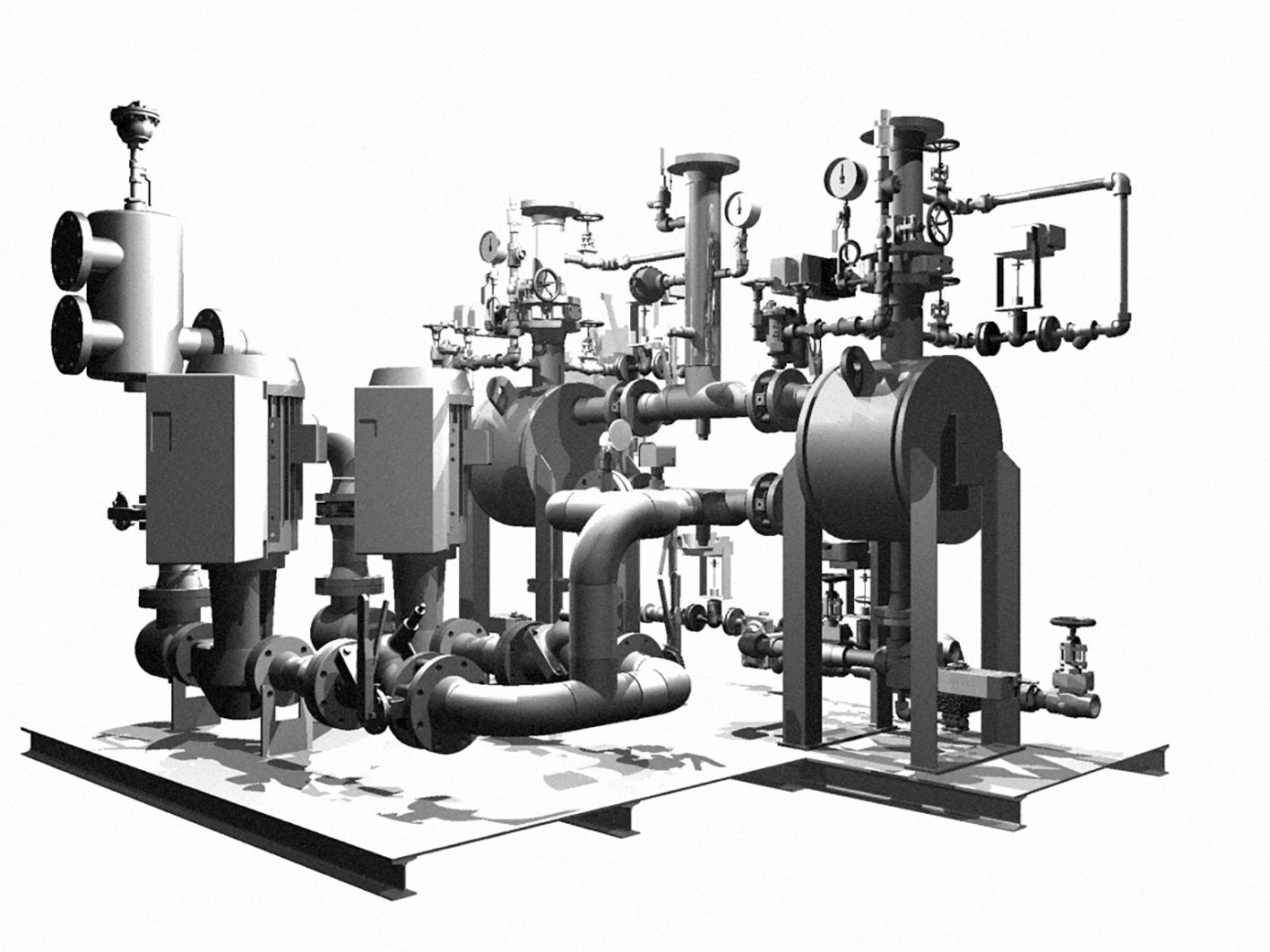

And so the success story began! Vahterus, provided us with the Plate & Shell Heat Exchanger design. Their technology made it possible to manufacture skid assemblies that can handle large loads and take up a much smaller footprint in mechanical rooms. Older buildings could easily be retrofitted by moving these new packages through narrow hallways and elevators. Newer buildings could take advantage of the compact footprint and use the saved space for real estate.

The success of these packages eventually led to the trade marketing of COMPACKHEAT by Preston Phipps. Throughout the years, hundreds of these packages have been sold across the Canadian market. The move to this design has opened the doors to countless opportunities. Designs have become standardised and many facilities are slowly replacing their older systems and adopting the COMPACKHEAT way of thinking.

Vahterus Plate & Shell Heat Exchanger technology combines the superior heat transfer of the gasketed platetype heat exchanger with the Shell & Tube tolerance for pressure and temperature. These highly innovative design characteristics in such a compact product, and our continued partnership with Vahterus, have allowed us to succeed.

Although Vahterus and Preston Phipps are in different countries, they share common values. Delivering a high-quality product, attention to detail and customer service are just a few examples of the appreciation and trust that our companies have for each other. Both organisations share business models that include re-investment, growth creation for valued employees and the willingness to meet objectives and challenges.

Download the full case study as a PDF

Transform your project with Vahterus Expertise

Interested in working with us? Our team of experts are ready to collaborate with you. Contact us today to embark on a journey towards cost-effective, sustainable and energy-efficient heating solutions.

Discover more of our Customer Stories

CO2 Cold Store Operates with Energy Efficiency and Sustainability in Eastern China

Yonghai Yi, Senior Sales Engineer at Vahterus China ...

One Vahterus Combined Chiller Cools Two Ice Rinks in Maryland

Jonathan Pascoe, President at Vahterus Americas and Mikko Tuomainen, Key Account Manager at Vahterus In September 2019, Vahterus supplied PSHE 8/6HH460/1/1 unit...

Large Reboiler Units and Heat Exchangers to Ningxia in China

A large industrial centre focusing on energy generation and the petrochemical use of mineral coal is currently being built in the region...